Early 2017 Recap

Wiper Blade

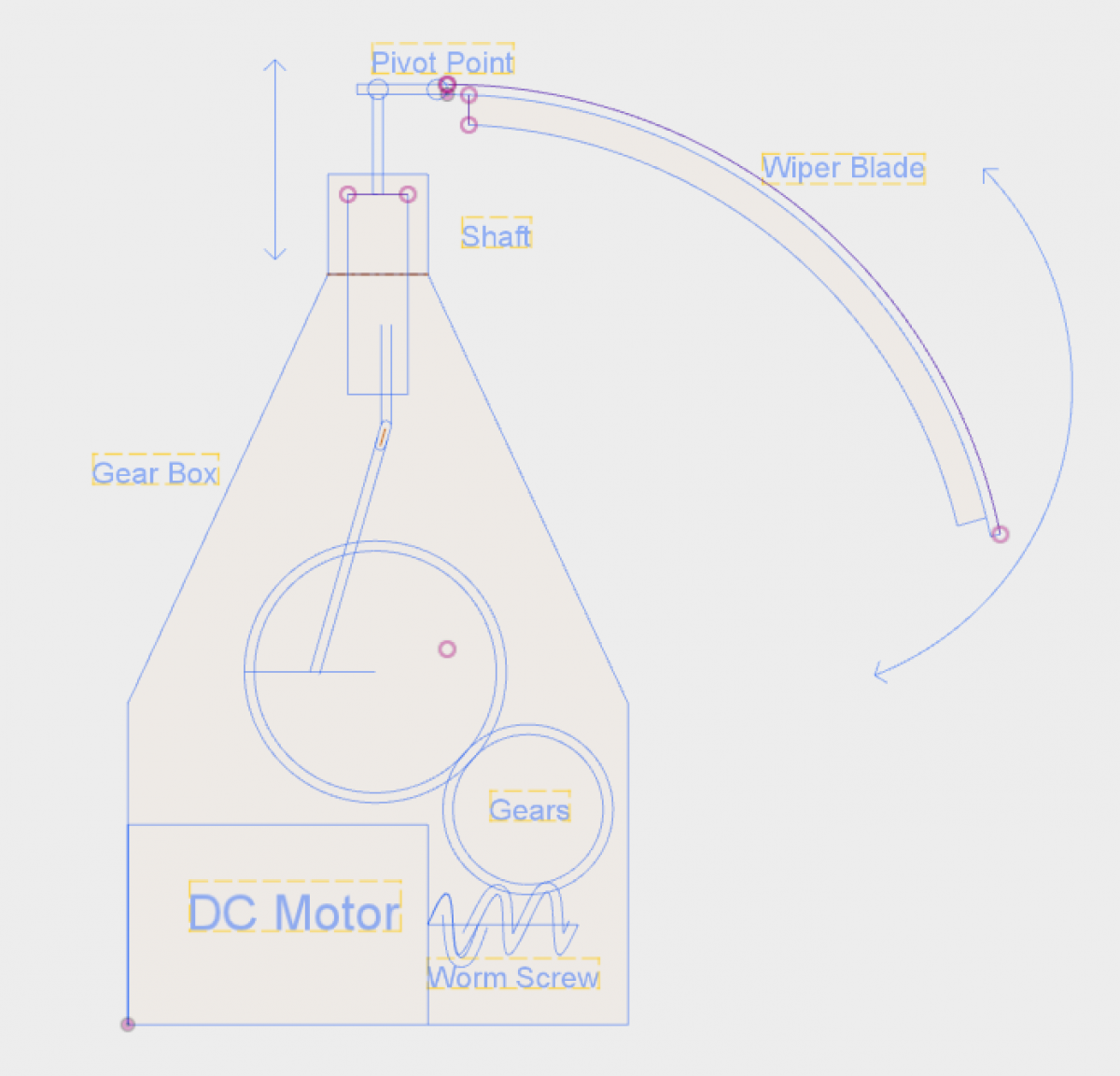

The construction of our wiper blade is coming along slowly but steadily! Earlier on during the month of February, we created a wooden prototype of the mechanics behind our wiper blade using balsa wood, plastic gears, and a standard DC electric motor. We were able to fit our wooden prototype into the SCBA Scott AV-3000 face mask, giving us insight about the amount of space we had to work with within the SCBA mask. The wooden prototype consisted of a motor, components made from balsa wood, two gears, and a shaft that translated the rotational motion of the gears into an up and down motion that moved the wiper blade. Using a rotary tool, we created a gear box, where most of the moving components would reside.

The DC motor was about an inch in circumference and did not take up much space inside the mask. The plastic gears are an inch and an inch and a half in diameter to decrease the speed of the motor. The shaft's dimensions are 0.5 inch in length, 0.750 inch in width, and 2 inches in height. Our main intention for creating the wooden prototype was to define the dimensions of our components so that our invention does not interfere with the line of sight nor work of firefighters.

Included in this summary is a video that we recorded of our W/B mechanism in early February to give you a visual of how the model works . . .

Heating/Cooling

As sustainability lead, one of our members studied a course in Sustainable Design from SolidWorks. Translating this knowledge to our team meant considering the impacts that our invention could possibly have on firefighters and the environment. Our primary concern was to not place firefighters in any unnecessary dangers while they used our invention. For the wiper blade team, we are taking precautions to prevent moving parts from distracting or hurting the wearer of the mask by slowing down the speed of the motor and adjusting the size of the wiper blades. For the heating and cooling team, human health is major concern, because we are dealing with electrical output and obscured vision. We are heedful of many factors that range from overheating the mask and possibly melting the lens of the SCBA mask to designing a faulty pattern of wires that would prevent firefighters from seeing. For example, one setback that we encountered this month was the adhesive vinyl on our electrical tape burning due to the heat from electrically heated wires and creating a small amount of smoke. This posed a safety hazard, as PVC releases toxic fumes when burned. As we proceed with our invention, we are listing out our problems and creating solutions by continuing to test different materials, designs, and approaches.

Mid-Grant Technical Review

After our MGTR, our technical lead, administrative lead, and one of our Educator Supervisors (Isaias Ramirez, Orion Jefferson, and Mrs. Mo Wong, respectively) were discussing the next steps we need to take for the actual product to be built. We decided that if we wanted accurate components to fit inside the mask, the components would have to be 3D printed. For the past month, the wiper blade team has been using the computer drafting software Fusion360 to design and print our prototype. After spring break, we expect to have all the components 3D printed and ready to be assembled. In the upcoming weeks, we want our design to be based on a four-bar linkage system with a few added components to help move the wiper. The problem with our linkage mechanism is that the wiper blade will only be able to move in one direction. Unless we create a completely different mechanism, add more linkage components, or reverse the polarity of the DC motor, we are dealing with this setback by testing out different orientations. The mechanical and electronic aspects of this invention is a little complex, especially with the limited amount of space in the face mask, but we will continue to research, experiment, and build.

Financial & Communications

In the month of February we have spent $187.74 on materials for our project and $109.90 on fundraising for our trip to MIT this June. Totaling a sum of $297.64 in the month of February alone, we have a remaining balance of roughly $3,300. Our efforts of fundraising toward the trip include hosting concession stands during competitive sporting events at our school and selling candy fundraisers.