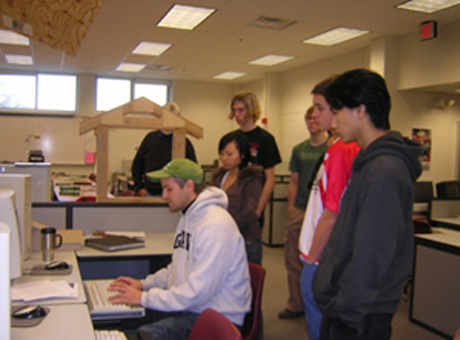

Johnson High School InvenTeam

The InvenTeam looked internally to solve a problem within its school: Each year the school spent close to $5,000 on wood for its wood shop class and other projects, of which 30 percent was rendered useless as accumulated sawdust. In a quest to create a product that was less dependent on energy and utilized recycled materials, the students’ Eureka! moment brought the realization that a complementary use of heat and pressure will cause the sawdust to bind to itself in lieu of using a petroleum-based material such as wax to mold the sawdust together. After building two press models, the InvenTeam determined a continuous-extrusion process device would be best. The InvenTeam partnered with school neighbor 3M, which provided mentors, machine parts, and other funding. "I really enjoyed this project. It taught me to be patient. It taught me to develop an idea and work with people well to voice my ideas and opinions." - InvenTeam student Will Anderson