Pneumatics: An Essential Part of Our Invention

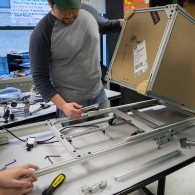

April has certainly been a long month for us. Despite Spring Break, we still had to work hard with the upcoming deadline. First and foremost, we are finally on our last prototype! Before that, we encountered many obstacles. Some of them include not knowing how to assemble the pneumatic cylinders, the late arrival of the plexiglass, and difficulty creating the frame for the prototype. Fortunately, with the help of our enthusiastic mentors, we were able to figure out how the pneumatics work, and even attached it to our penultimate prototype to see if it would work.

The initial idea for our final prototype is to have a total of five pneumatics: one for sliding out the storage compartment, another two for lifting up the ends of the storage, and finally another two for each side of the door. Our idea is to have the storage slide backwards, past the flatbed; after, the pneumatics will tilt it downwards, where the door will open and release the garbage. The trash will then end up in one of the underground compactors.

Another obstacle for us was the cutting of our final prototype’s plexiglass. The problem was that we didn’t have the tools necessary to effectively resize it. At first we tried using the jigsaw tool, but it melted the acrylic and did not make a smooth cut. As a result, we used an acrylic cutter and scored each end. The process was time consuming but created a perfectly straight edge. Now, the only thing for us to do is to slide in the plexiglass and make sure that it fits the 80/20 frame perfectly.

In other news, we have been interviewed by a newspaper called the World Journal. As if that wasn’t enough good news, we also have an upcoming presentation in front of Liz Krueger, a New York State Senator, who will be coming to our school!