New Expert Friends

By Chloe Landau

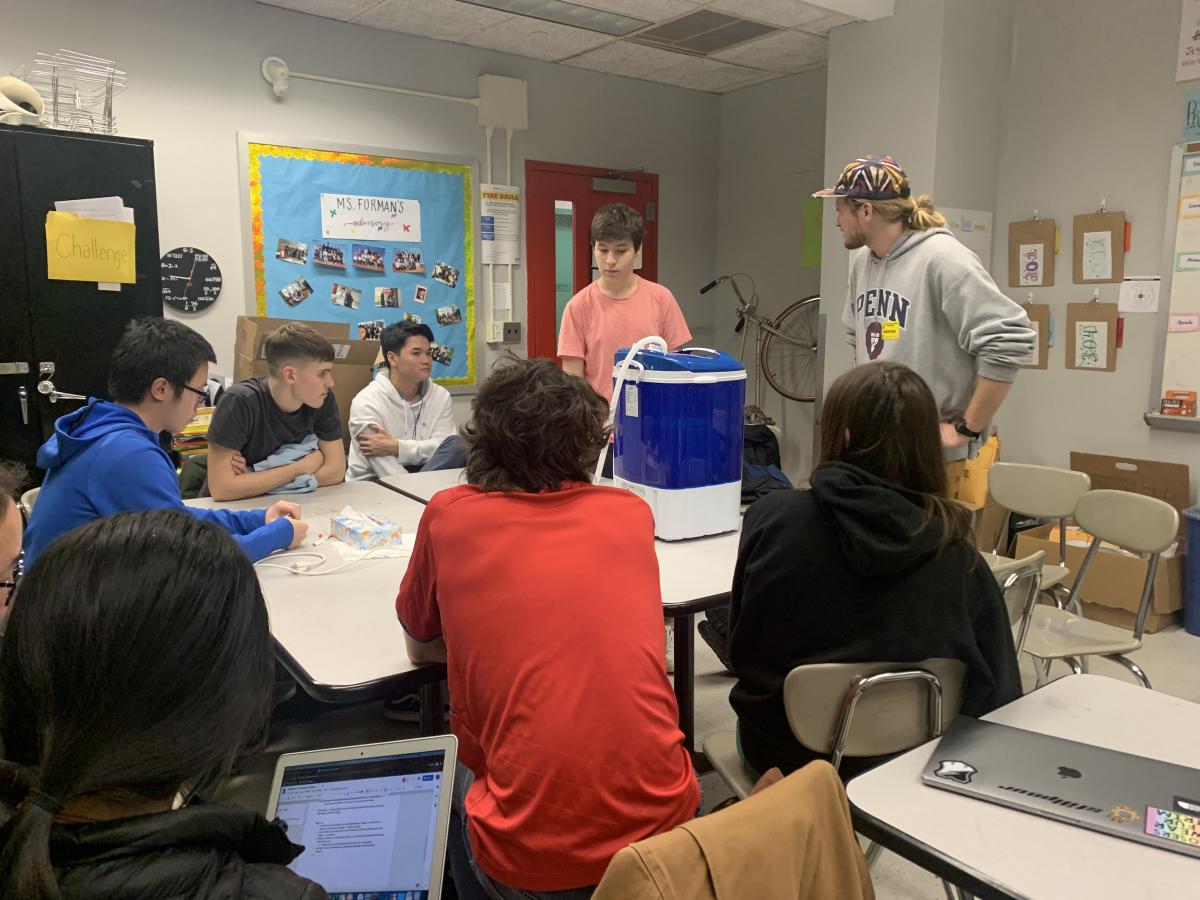

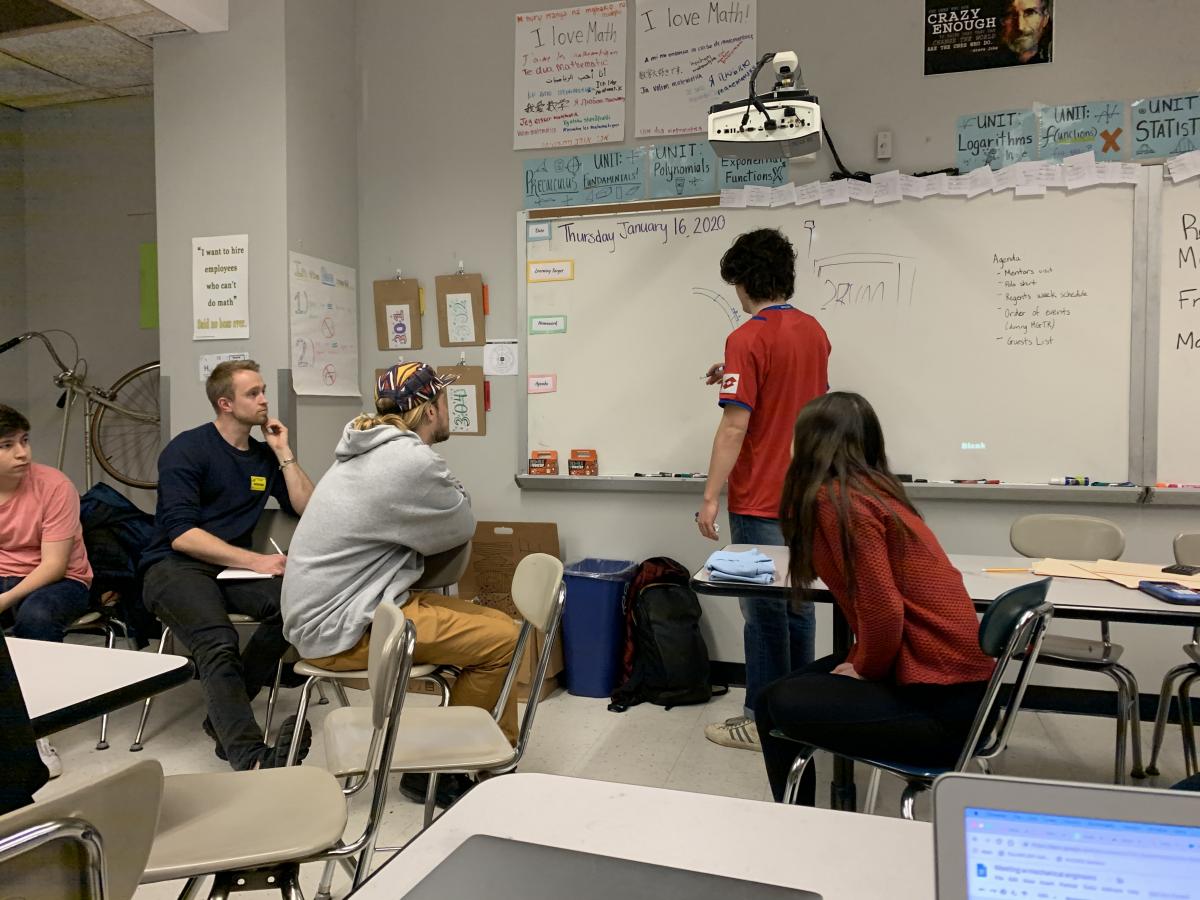

By January 16th, we had already laid the groundwork for our machine, but we knew that there would most likely be gaps in our knowledge since none of us have rigorously studied mechanical engineering. Guate Wiig Nordby and Zac Bensing, recent graduates of UPenn’s Masters of Integrated Product Design program, were willing to consult with us about our machine. We are fortunate to get insight from these already accomplished innovators: Nordby is Co-Founder and Chief Technology Officer of Wim, a sustainable single-use beverage system, and Bensing is a product designer currently working for a bidet company (aptly named Tushy).

While reviewing our machine with them, they emphasized that all decisions need to be based on what our users want. This brought up new questions: How long would kids be comfortable riding for? Are there common allergens in soap nuts? Would the experience be more fun for the kids if we could incorporate competition games? How would they feel about their clothes being hung to dry? We want our invention to be a facilitator in community building, so we will be going into the school this week ask these questions. We don’t want our machine to be popular for a week and forgotten about after.

We also discussed technical points. We realize that a typical warm wash lasts 30 minutes, outlasting the time an elementary schooler can pedal on a stationary bike. We hypothesized that increasing the power generated to then increase speed and water temperature can cut down the wash time, so we want to connect multiple bikes to the machine. We also want to keep wash times under 15 minutes. We understand that the majority of power generated would go towards heating the water, especially with a bigger load, so we hope to connect our machine to the heated water in the building to cut down on energy needed.

We had decided weeks ago to consider soap nuts, a natural surfactant (substance that lifts stains), instead of detergent because they are extremely sustainable — one package lasts over 1000 washes. Guate and Zac reminded us of our ultimate goal — to effectively clean clothes — so we have to make sure that the washed clothing meets the Sanitation Performance Standards. After our meeting, we compared the results of clothes being washed with soap nuts versus with a name brand detergent. We found that the soap nuts are much less effective at lifting stains and leave a pungent smell. We will continue searching for solutions to address the shortcomings of the soap nuts. In addition, through these experiments we found that 90 degrees Fahrenheit is the optimal temperature to wash the clothing.

We are currently implementing the feedback our mentors gave us and we will continue to work with these professionals throughout the building process.