March Post MGTR and Sustainability Update

The R2i2 InvenTeam had a very successful Mid-Grant Technical Review Presentation and received wonderful feedback as well as suggestions from the audience that attended (To view more details from out MGTR check out Twitter ). Some members of the audience would have liked to see more detailed information on Senegal. With this topic, we would be able to relate to how important the concept of sustainability and the idea of our module is one that can be easily reproduced with materials that are easily accessible in a broader light.

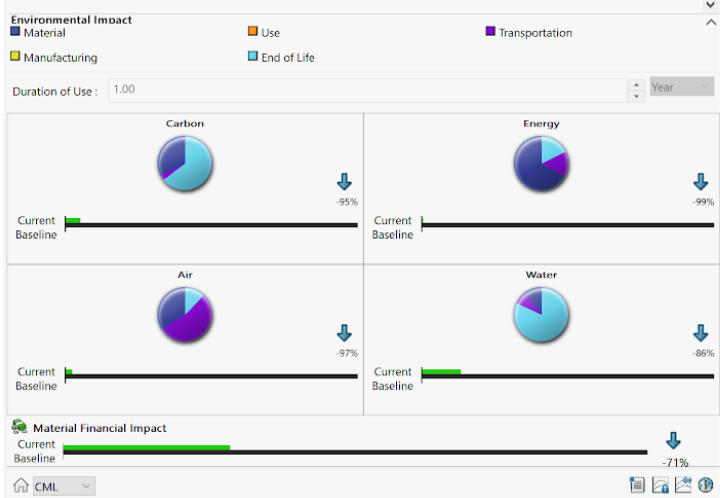

For the Mid-Grant Technical Review, Sustainability Lead Kay Brown presented information from Solidworks Program Sustainability. There are four comparisons of various materials from different regions. Comparison #1 demonstrates Balsa Asian wood vs. ABS North American plastic, comparison #2 Asian ABS plastic vs. Teak Asian wood, comparison #3 Asian ABS Plastic vs. North American ABS, comparison #4 ABS vs. pine wood.

Currently, our prototype is 3D printed from plastic. Taking into account that Sare Bilaly, Senegal does not have access to a 3D printer, our final invention will be produced from wood. Sustainability program not only allows you to specialize in the region and material chosen but also allows you to analyze in further detail, in four major areas. These areas include Carbon, Water, Energy, and Air. When comparing between ABS plastic and pine wood, pine wood was seen in all four areas to have decreased, making it a more reliable and adequate.

There was concern about deforestation or forestry practices in Senegal. In Senegal, the land is divided into regions which are then divided into sections. Only 1 or 2 of those sections each year are allowed to be harvested for charcoal. Regulations are also in place for how the tree must be cut in order to let the seedlings grow again. Finally, the land is off limit for harvesting for 8 years. There is also a size restriction of trees. These practices combined make for sustainable forestry practice in Senegal. And with the skilled carpenters in Senegal finding pine wood and carpenters to build the module box will not be an ordeal. In the upcoming months, “I will continue using the Solidworks sustainability program to see how changing the modular box size impacted sustainability.” -Kay Brown, Sustainability Lead