December Update: Prototype Refinements

After two week of tiring work, the team has made big strides in completing the system. We still have refinements to make, but we are well on our way to begin testing and recording data.

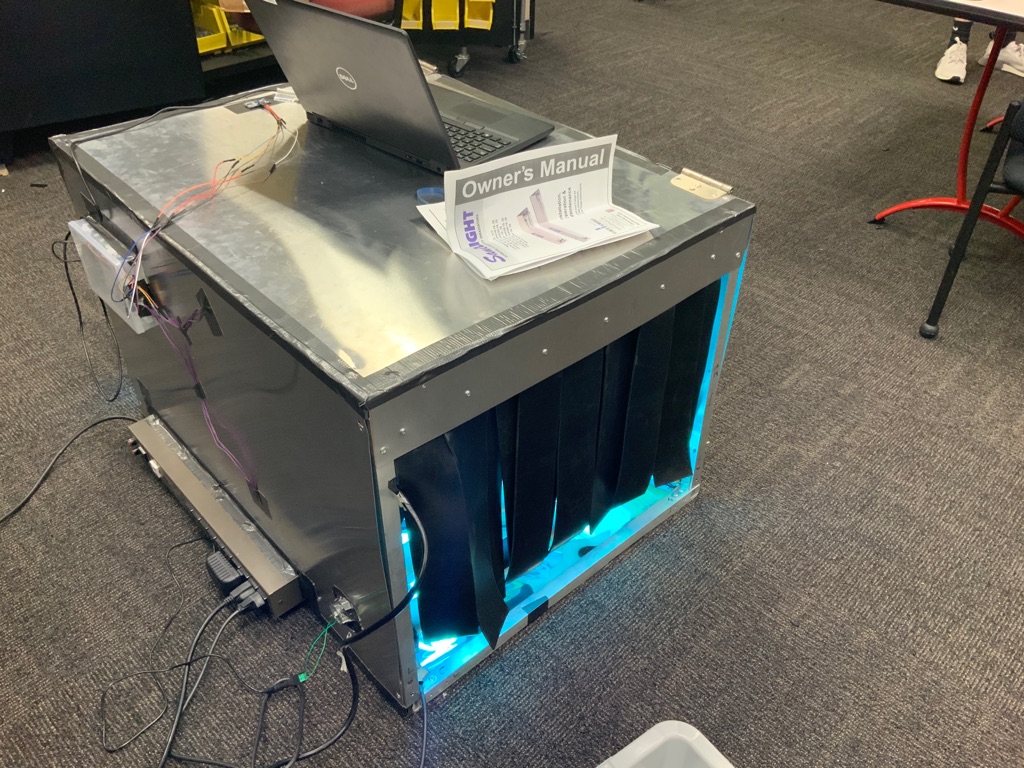

As noted in the previous blog, the rollers did not work the best when chained with rubber bands. Our decision to incorporate sprockets made mounting the drive motor significantly simpler (see rear left roller). The sprockets ensure all rollers rotate at the same angular velocity, and our new motor has a more precise RPM (our previous motor was battery driven, so voltage wasn't constant). The black strips along a couple of the rollers are grip tape, which help in pushing the bin through heavy flaps. The reflective material along the surfaces is mylar, which we opted for instead of polished aluminum. The material was much cheaper, and we believe that the random crinkles will actually be beneficial when reflecting UV.

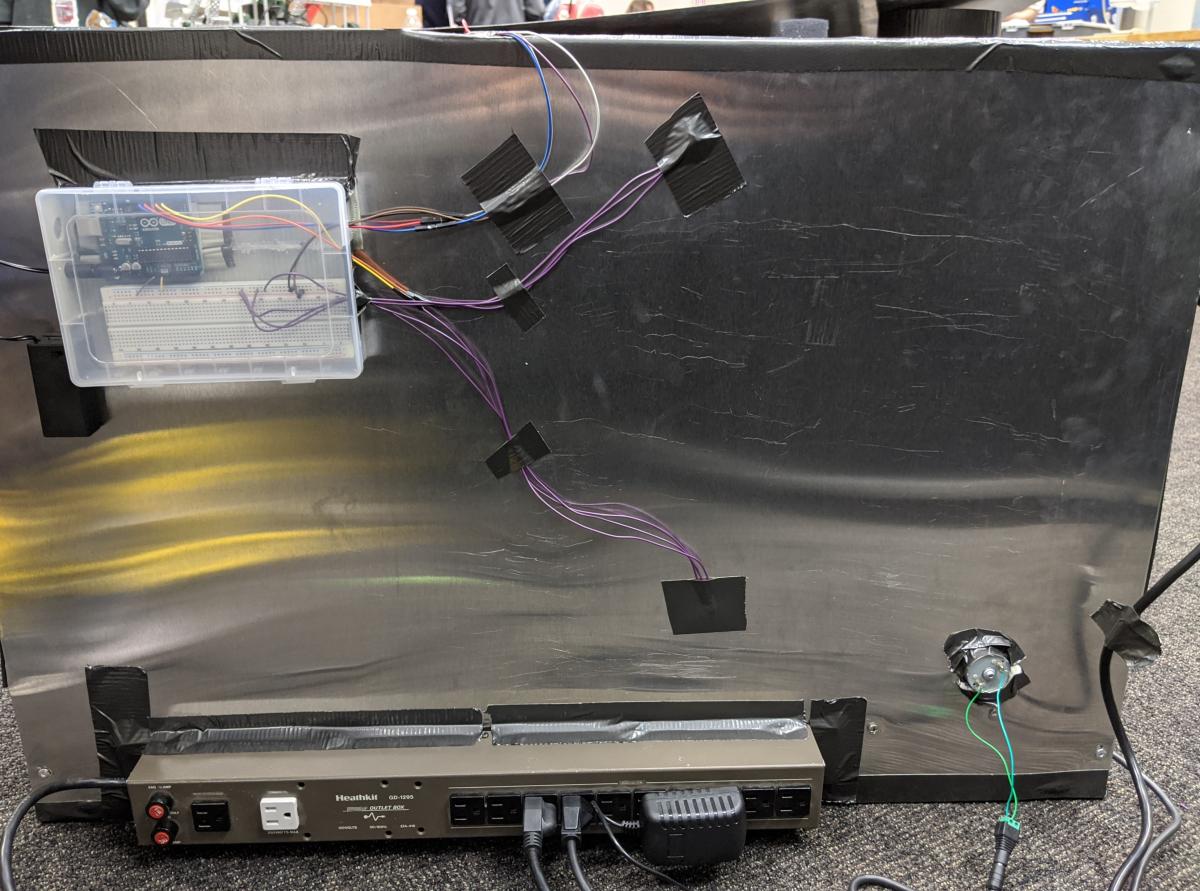

You can probably tell by now that our team has mastered the art of mounting with duct tape. Because our prototype is so temporary, we decided duct tape would allow for easy modification. The plastic box on the top left houses the control system, which is simply an Arduino and breadboard. The bottom right is where the motor sticks out and connects with an AC/DC adaptor. The lamps, motor, and pump are all connected to the power strip on the bottom to make powering the system on and off as simple as possible. Future additions will include a more compact power strip, wire sleeves, and another container for our spray solution. For now, testing will be done by manually spraying the solution.

With the UV lamps finally turned on, it is pretty clear that our flaps bleed too much light (though it is hard to deny that the blue glow does not look cool). We will continue to look for new solutions, including extended side panels.

Here is a preview of our machine in action. The chamber is meant to be installed into pre-existing systems, so you can imagine the bin continuing onto another conveyor instead of falling. This was for demonstration purposes, so our conveyor speed is by no means final. With our initial prototype finished, we were ready to deliver the system to the biosciences group.

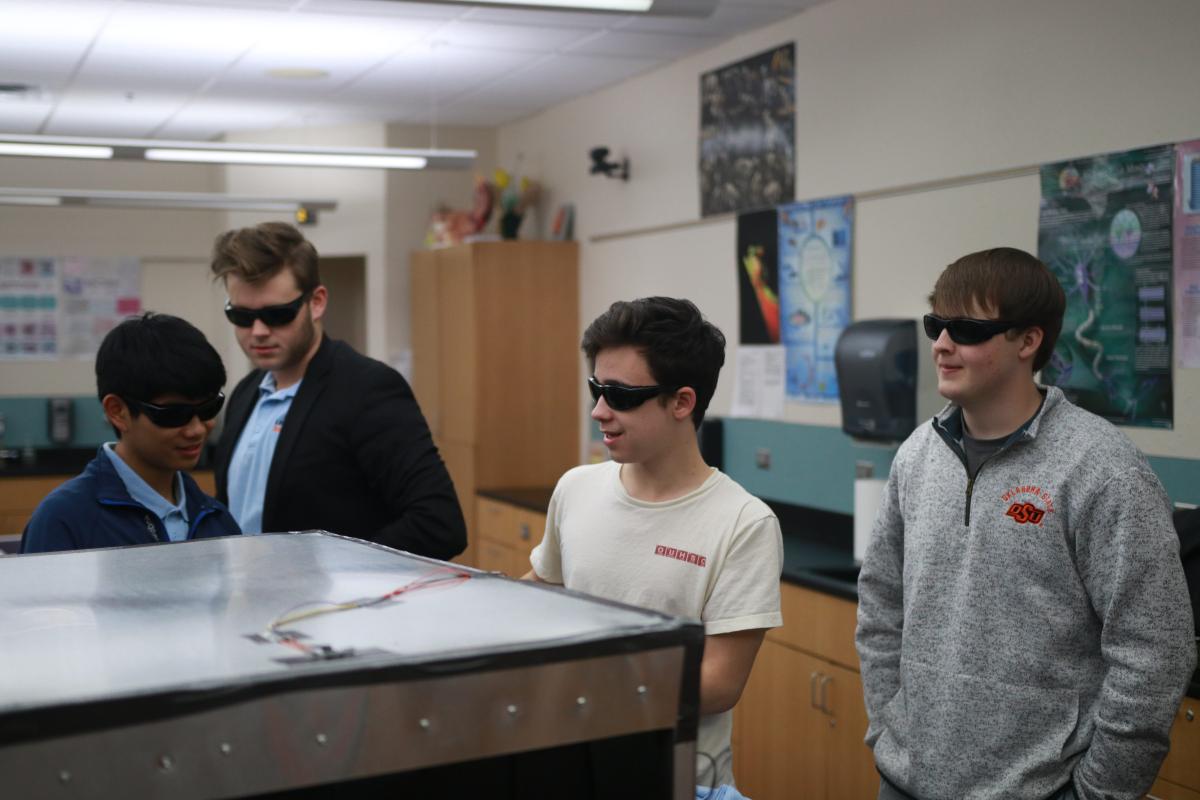

At the meeting, we got had our polo photoshoot and demonstrated our solution to the biosciences group. They learned how to install the bulbs and power on the machine. The glasses we are wearing are designed to prevent eye damage due to the light bleed mentioned earlier. With the team ready to begin testing, we are excited to show our testing methology and results in our next update!