Answer Part 1: Abrasion

To start, we know we need to get the gum off of the concrete without harming the surface. After sampling various brush types, we have narrowed down our selection to brass, nylon, or steel brushes. We have chosen these ones due to their ability to remove the adhesives effectively without being too expensive. One of the things we want to avoid are “clean stains” -- which occur when the area of the removed gum is whiter/brighter than the surrounding concrete-- as those are just as unsightly as a gum stain or a leftover piece. The gum is much easier to remove after being exposed to heat, so we know heat will have to be applied before we start the abrasive removal process.

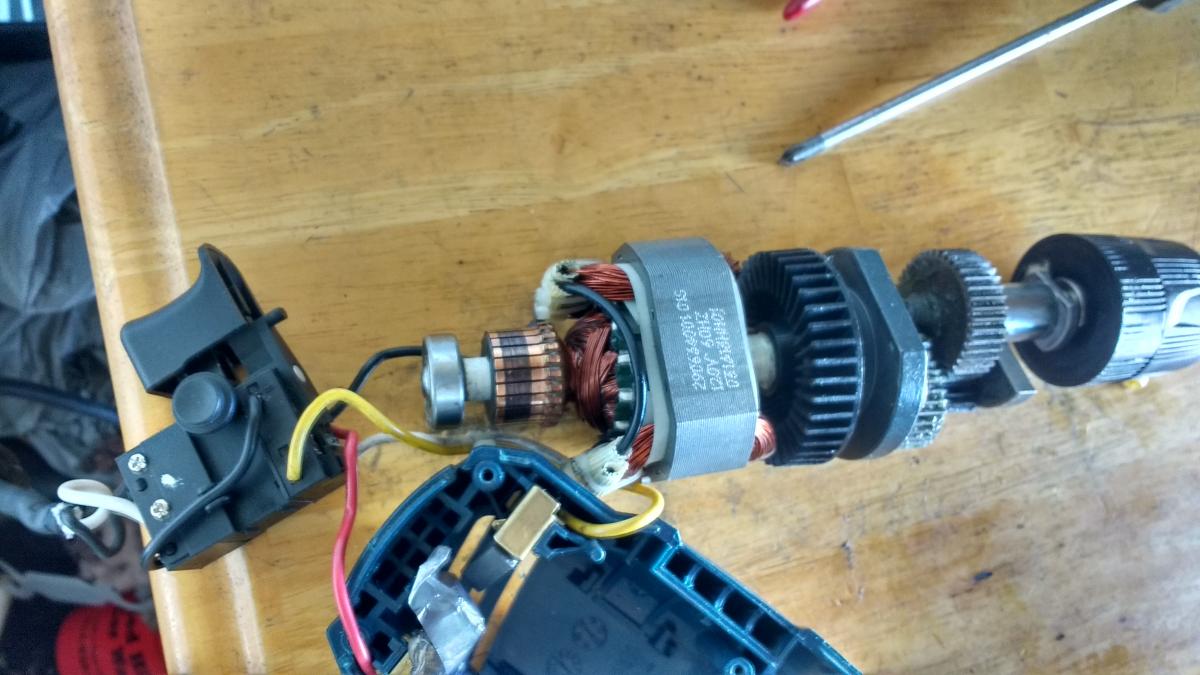

The brush will be locked at the end of a keyless chuck extension which is locked into a drill that has been section cut in order to maximize the space efficiency of the device. The drill is then connected to a push button as well as an AC/DC power supply which gains power from being plugged into an outlet. The system will not let power into the drill until the button is pressed.

The process of removing the gum starts with first applying heat to the adhesive for roughly 15 seconds, then the substance diluted with water is poured onto it. It is left to sit for about 10 seconds before the abrasion process starts.